Handcrafted Surfboard w/Luka

- Mackenzie Campbell

- Oct 11, 2024

- 2 min read

Updated: Oct 13, 2024

My recent endeavor had me in the shaping studio assisting my boyfriend Luka with a one-of-a-kind surfboard project. The project fused craftsmanship, heritage inspiration, and upcycling to design a distinctive surfboard inlay, showcasing a hand-carved wooden block print on a thrifted sheet of linen.

The Vision

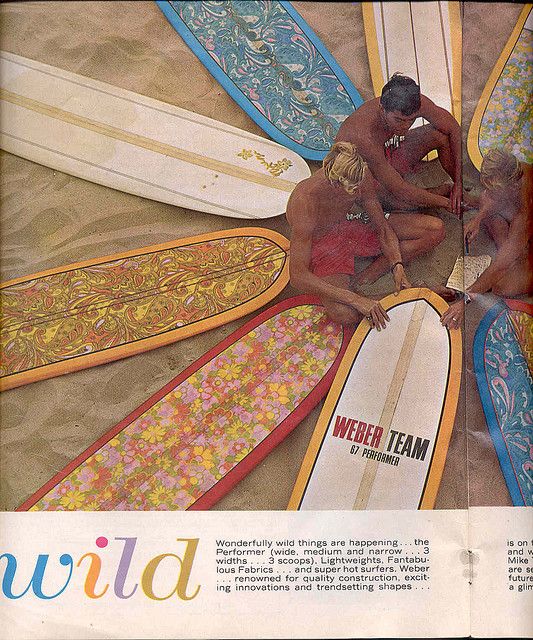

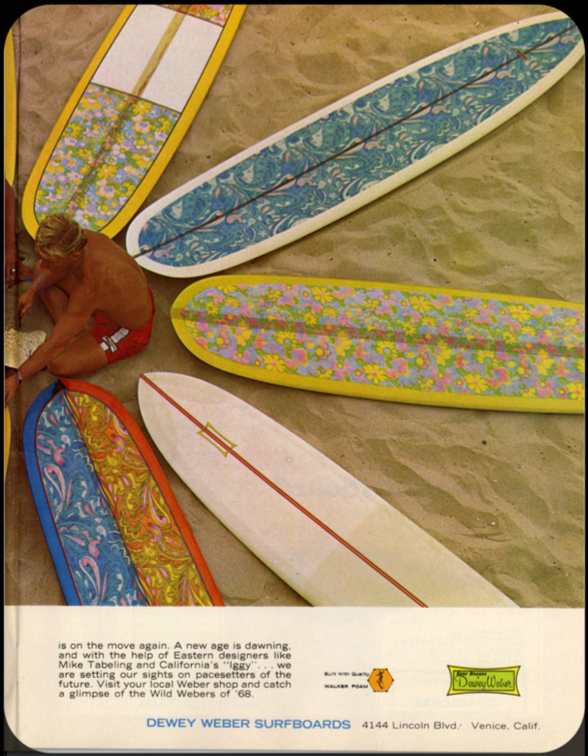

Our board was inspired by the surfboards of the 1960s-70s, an era that celebrated form, function, and funk. During this period, surfboards were not just about performance; they were canvases for artistic expression. The vibrant colors, bold patterns, and innovative shapes of that time influenced our design, guiding us to create a board that echoed the spirit of those hippy surfers.

Shaping the Board

Using a 9'3" polyurethane reverse rocker foam blank with a 3/8" red cedar stringer, Luka shaped the deck foil, bottom contours, and rail bands with precision, using the iconic Skill100 planer—an essential tool for surfboard makers since the 1950s. We sanded the board to a smooth finish after adding a custom Douglas fur tail block and refining the curves.

Hand Carved Wooden Block Print

The centerpiece of the project was a floral design, hand-carved into a wooden block and printed onto a thrifted sheet of linen. This step required precision and skill, blending the time-honored tradition of block printing with modern surfboard making. The printed fabric was carefully inlaid onto the surfboard, ensuring it aligned perfectly with the board’s contours for a seamless look.

The Inlay and Fiber Glassing

The process of inlaying the printed linen onto the surfboard was delicate and intricate. The fabric had to be carefully cut, aligned, and smoothed onto the board. Laminating over the linen added another layer of complexity, as the resin and fiberglass cloth (7oz Volan fiberglass with polyester resin) had to be applied with precision as it is the first layer of the fiberglass shell to encase the foam shape.

After draping the fiberglass sheet over the board and laminating it with resin to follow the contours, we performed a hot coat. Wax was added to the resin in the hot coat to create a sandable surface, allowing us to sand the board smooth. The final steps included adding resin pin lines and applying a gloss coat for a sleek, polished finish.

The Result

The final product was a surfboard that showcased transformation—wood shaped into design, thrifted linen integrated as an inlay, and a blank board finished into something functional and unique. The fiberglass encapsulated the floral print, highlighting subtle connections to nature and the lakes.

The Essence of Craftsmanship

This project was a clear reminder of what true craftsmanship requires. It’s not just about making something—it’s about executing each step with precision, respect for the materials, and a clear vision. It’s about recognizing potential in discarded fabric or a plain surfboard blank and transforming it with skill and creativity. In a world full of mass-produced goods, there’s real value in creating something by hand. This surfboard isn’t just functional; it stands as proof of the artistry and dedication that go into genuine craftsmanship.

.png)

Comments